Guide your manufacturing business toward profitable growth with less complexity

A guide to selecting the right business management solution for your growing business

As a manufacturer, you’re always looking to streamline operations while fueling growth—so you need to take a hard look at the way you organize, share, find, interpret, and use your data. That’s because managing growth is all about making quick, smart decisions, which requires easy access to timely, relevant information. With data increasing dramatically in both volume and complexity, the tools you use to manage it will have a big impact on your bottom line.

Whether you’re managing your operations manually, using basic accounting software, or relying on an outdated, legacy ERP system, now is the time to consider a new businessmanagement solution. Faster, simpler, and more flexible, today’s business managementsolutions offer advanced, integrated features such as mobility, analytics, dashboards, and alerts. Functionality like that will enable your users to easily access the information they need, and convert that information into smarter, faster decisions that drive growth.

Of course, selecting the right business management solution can be challenging and requires in-depth preparation and research. According to one report:

- 64.3% of companies required moderate to heavy customization

- Most chose a hybrid implementation approach to rollout a new solution

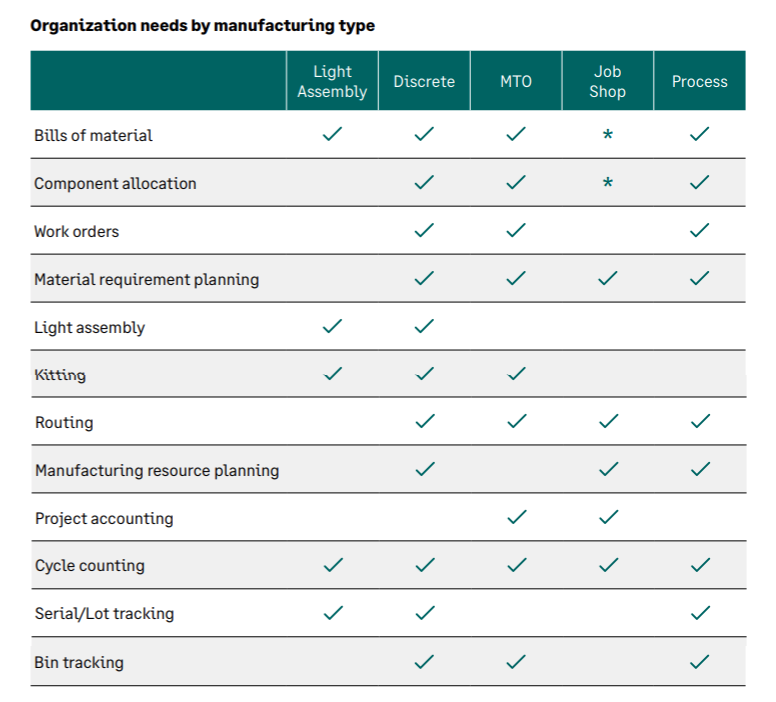

Every manufacturing business is unique, with different processes, tracking systems, and problems. Your business requires a business management solution tailored to your specific needs. To help you narrow your search for the right solution, select the type of manufacturing that best represents your business.

Light assemblers (or assembly manufacturers)

Create products by assembling or groupingcomponents purchased from other manufacturers. Most have very few requirements for extensive production scheduling or workflow management.

Discrete manufacturers

Make the same product over and over again and depend heavily on forecasts to purchase raw materials at the right time and cost.

Make-to-order (MTO) manufacturers

Respond to customer demands by producing entirely new products, or significant modifications to standard products. Accurate product definition and costing are important objectives.

Job shop manufacturers

Rarely make the same products twice. Instead they assign material costs and labor costs on a project-by-project basis without much repetition.

Process manufacturers

Produce batches and typically involve mixtures and chemical processes that make estimating required materials and finished goods somewhat complex. They may produce the same product over and over again or they may mix custom batches on a project basis.

Questions to ask your vendor

As you narrow the field of contenders, start examining the companies more closely to see how well their business management solutions address your needs. Consider asking these questions to identify the solution that best fits with your long-term strategy to achieve manufacturing excellence.

What accounting modules are available?

A minimum set should be able to generate sales orders, invoices, and financial forecasts automatically, not only reducing data entry time, but also the need to be so reliant on spreadsheets. You may also want to ask about additional modules such as payroll, fixed assets, or other manufacturing modules.

Which manufacturing modules are available?

Light assemblers should look for a business management solution that offers features such as bills of materials (BOMs), sales kits, and product configuration. Discrete manufacturers would benefit from material requirement planning and manufacturing resource planning in addition to support for BOMs. Make-to-order and job shop manufacturers will likely need all of these features plus a method for estimating and tracking costs on a project-by-project basis. Process manufacturers will require many of the aforementioned features, as well as serial and lot tracking, bin tracking, andcomponent allocation capabilities. Reference the chart on page 4 for more details.

Do the accounting and manufacturing modules integrate completely?

Just because the modules come from the same company doesn’t mean they work together. Find

a solution that can unite all business functions, becoming the one piece of software into which all information is entered and processed. Check to see that BOM and manufacturing orders have a solid integration with inventory control and sales orders.

Is the solution designed for your business?

Before you tell your vendor about your business, find out what they think their solution strengths

are. You’ll get a good feel for whether or not they design solutions for small to medium manufacturing companies like yours, which are usually looking for solutions that are more cost and operationally effective than a full-scale ERP implementation.

Does the solution have the capacity to grow?

If you’re not sure how well a solution will accommodate your company’s needs as you grow, here are some key questions to help you find out. What are the maximum number of customers, vendors, BOMs, or inventory items that are allowed? What is the maximum number of users that can be working with a particular application at the same time? Can the solution be configured to meet the changing needs of a growing company?

Can the solution help my productivity?

You will need to consider how well the business management solution monitors your critical work areas. Can you monitor production if you’re running at 100% capability for your staff? Has inventory been received, and if so, are the counts reliable to accurately forecast material requirements? Data collection ties into true manufacturing as well as accounting. How well you collect vital data determines your ability to forecast production information.

Is the solution easy to use?

If you want a business management solution that delivers maximum productivity, focus on how easy it is for your employees to use. You want a solution that lets you enter information quickly and efficiently and is able to handle all the situations that can come up on a day-to-day basis.

Do you have a choice on how to deploy?

Choosing between on-premises or cloud deployment can be difficult. It’s important to

consider your company size, business complexity and processes, expected growth, and the sophistication of your current IT skills and infrastructure when weighing up your options. With cloud, you have the benefit of getting real-time access to your business data anytime and anywhere.

How many people are currently using this solution?

A large install base means the solution has stood the test of time, satisfied companies similar in size to your own, and delivered good value. If the solution is popular, you’ll find add-on software, worthwhile utilities, a training schedule with convenient dates and locations, and a large number of local dealers who can work with you.

Questions to ask your consultant

Your ideal consultant is someone who has installed manufacturing solutions at similar companies. Having been through the process before, their expertise can save you time, money, and effort. Here are a few questions to help get you started in finding a business partner that’s right for your business.

Have you installed manufacturing solutions at companies like mine?

Ask about company size, number of employees, and nature of the business.

Can you provide references?

Ask for contact names so you can call these customers and learn about their implementations.

How are your fees structured?

Find out up front how your business partner handles hours, services, and billings.

Can you provide a complete service package?

As part of your implementation, you’ll need training, technical support, and many other services. Look for a business partner who will work with you from start to finish instead of someone whose only focus is on selling the solution.

What does it cost to add more users or more modules for existing users?

When you’re running price comparisons, dig a little deeper than initial cost. In addition to considering maintenance and

upgrade support and costs, think about how much you’ll pay to add on more users and/ or modules, worthwhile utilities, a training schedule with convenient dates and locations, and a large number of local dealers who can work with you.

Who is responsible for the technical support?

Will you call the vendor or the business partner? How much will technical support cost? Find out what the policies are for maintenance, upgrades, and support. Ask about support turnaround times.

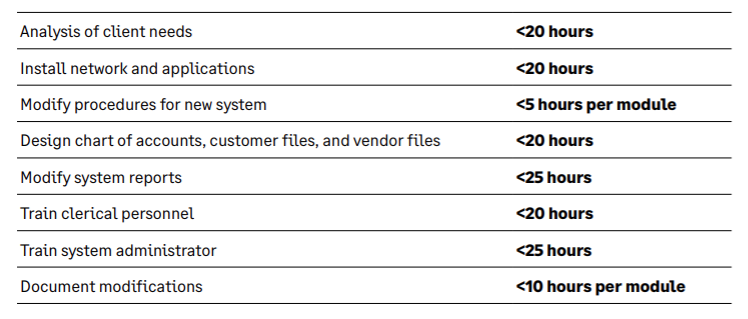

Calculating consulting costs

Consulting fees will depend on the requirements of the implementation’s local pay scales, expertise, and more. It’s impossible to predict exactly how long your installation will take or how much it will cost. Sage 300 typically has a quick and simple implementation process. The chart below provides some insight into timelines of a robust implementation.

You may have additional costs—and some savings—if your accounting and manufacturing systems are already automated.

Now is the time to seize the moment

Choosing the right business management solution can be challenging, but it’s worth the effort. The right solution can help you manage your entire manufacturing operation faster and more effectively—from procurement and scheduling to shop floor, inventory, sales, and financials.

For 35 years, Sage has been helping manufacturing companies like yours grow their business with faster, simpler, and more flexible business management solutions. Find out how we can do the same for you. Visit Sage 300 and prepare your business for growth today.